Behind the Factory

In Sepahan Moquette’s factory, each roll of carpet goes through a long journey from raw material to the final product.Fibers are opened and blended, turned into a uniform layer, consolidated through needlepunching, then textured, patterned, and colored; finally, they are finished, inspected, and packed into orderly rolls.On this page, we follow step by step the production of felt, velour, and printed carpets to see how they are made and prepared for delivery.

Opening & Blending: The Start of the Journey

In the blending stage, raw polypropylene or polyester fibers are fed into opening and blending machines.These machines open the fibers, remove knots and clumps, separate them, and distribute them evenly.Uniformity at this stage is crucial, as even fiber distribution creates a solid base for later steps such as carding, needlepunching, and finishing, directly affecting the carpet’s quality, durability, and appearance.

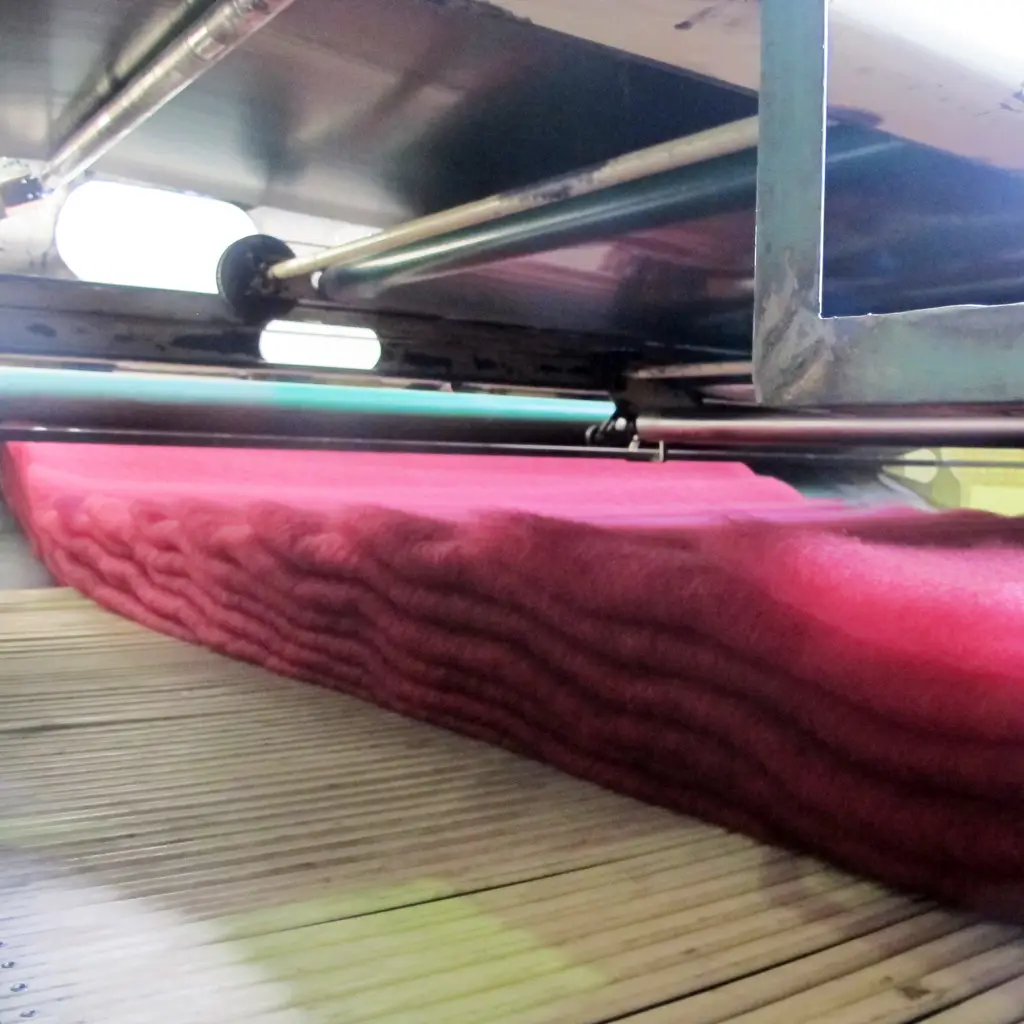

Carding: Turning Fibers into a Uniform Layer

In carding, the opened fibers enter a machine equipped with rollers covered in fine metal teeth.These rollers comb the fibers, untangle remaining knots, and align the strands in one direction.The result is a light, uniform, continuous layer called “web,” which does not yet have final strength.This layer is the foundation of carpet making and must undergo needlepunching to gain cohesion and durability.

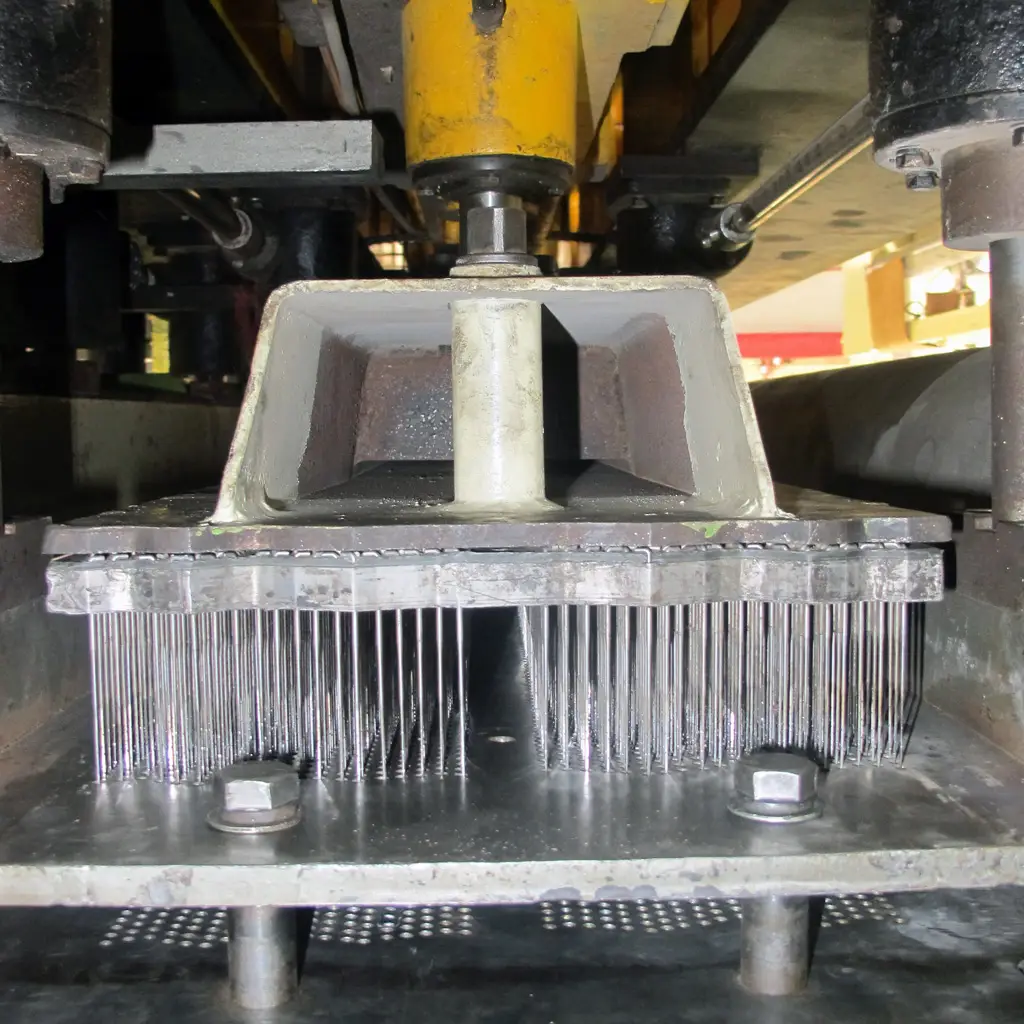

Needlepunching & Velour: Turning Fiber Web into Velvet Felt

At this stage, the fiber web enters the needle-punch machine.Thousands of barbed needles rapidly penetrate the fibers, mechanically interlocking them.This process creates a dense, cohesive, and durable structure.Immediately after, in velour carpets, the same layer passes through a machine that applies needling on one side and brushing on the other, creating a soft, uniform, velvety surface.The result is a carpet with upright pile and a velvet-like appearance.

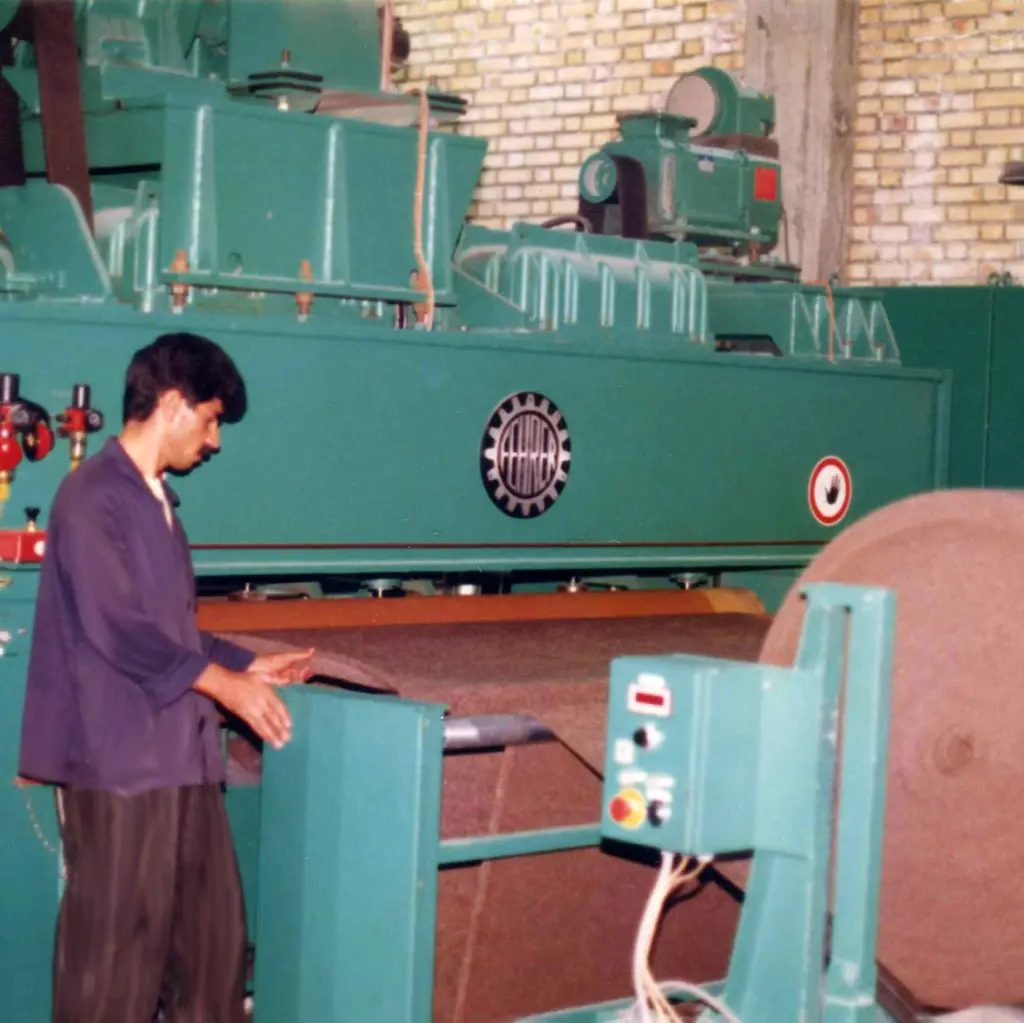

Jacquard or Hot Roller: Patterning the Felt

At this stage, the carpet’s final appearance is formed.Depending on the product, the felt layer may enter a patterned needle-punch machine (Velour Jacquard), where controlled needling creates patterns with defined textures and depth on the carpet surface.In other products, the visual effect is achieved through thermal embossing—passing the carpet under rollers with raised patterns that imprint designs onto the surface with heat and pressure.

Digital or Rotary Printing

The final look of some carpets is achieved by adding patterns and colors using rotary or digital printing.In rotary printing, patterns are transferred using perforated metal cylinders and rolling dyes—fast, economical, and suitable for repetitive, high-volume designs.By contrast, digital inkjet printing allows direct printing on white carpet, offering high precision, a wide color range, and full design flexibility.This method is ideal for custom orders, rapid prototyping, or projects requiring detailed graphics.

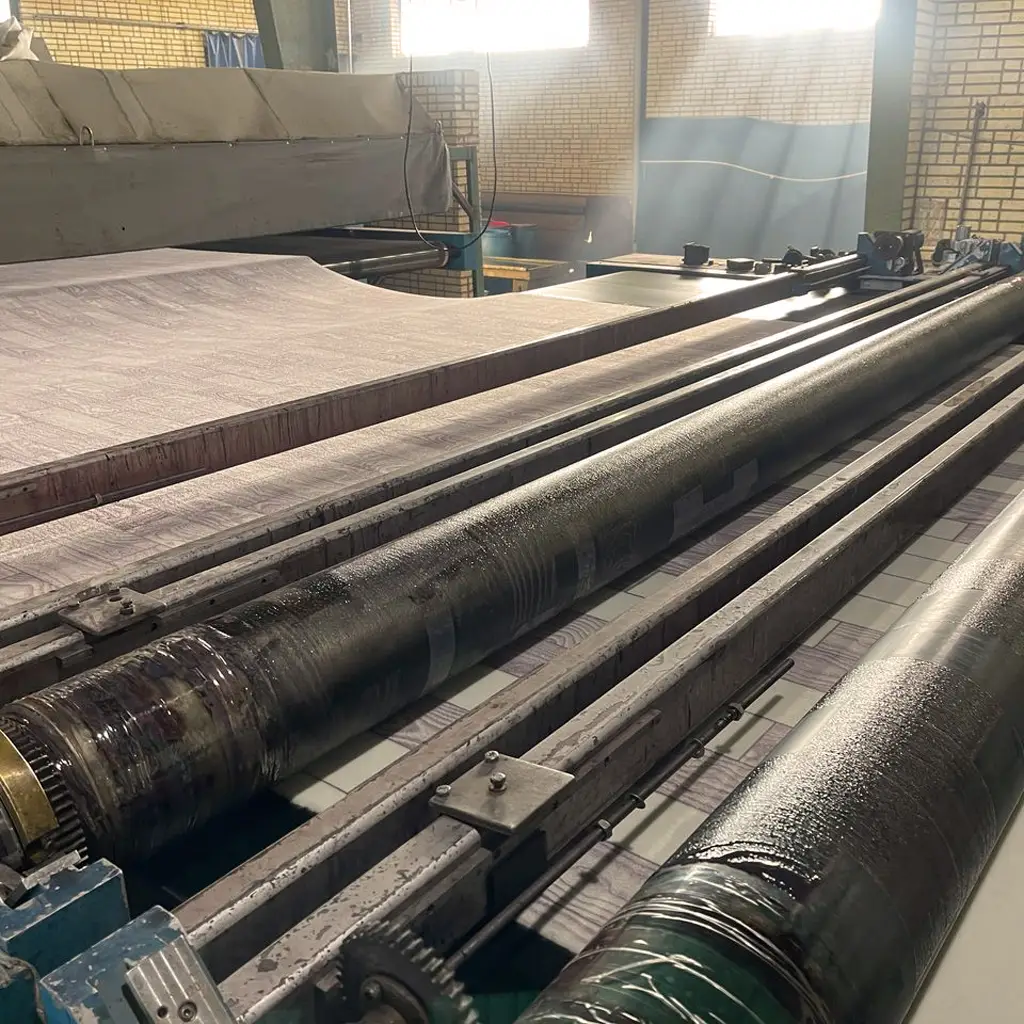

Final Finishing, Quality Control & Packaging

In the final production stage, carpets enter the backing unit, where they are coated with a layer of PVA (polyvinyl acetate) resin.This layer increases dimensional stability, secures fiber structure, and improves carpet performance in installation and use.After the resin fully dries, each carpet roll is inspected for appearance, color, thickness, design uniformity, and other technical attributes.Strict quality control ensures the product complies with production standards and customer orders.Finally, carpets are rolled, packaged, labeled, and prepared for delivery.

Conclusion

The behind-the-scenes process at Sepahan Moquette shows that carpet production is a combination of technical precision and design artistry.From fiber opening to digital printing and final packaging, each stage is carried out with strict quality control to deliver a standard product to the customer.If you are choosing a carpet for your project or space, be sure to read the Carpet Buying Guide to make the best choice.To learn more about cooperation and delivery stages, you can also visit the Carpet Ordering and Shipping Conditions page.